Bricks & Brickwork

Welcome to our comprehensive guide on brickwork. As a prominent construction company in with a long-standing history in the industry, we understand the intricacies and artistry involved in quality brickwork. Through this guide, we aim to explore different aspects of brickwork, from the types of bricks to the unique bonds, mortar use, and essential best practices. This guide serves as an informative piece for those interested in the craft and illustrates our appreciation for skilled brickwork contractors.

Brickwork Contractors

Brickwork contractors play an indispensable role on a building site, providing the expertise and craftsmanship that brings architectural designs to life. As professionals, they possess a deep understanding of different types of bricks, mortar mixing, and bricklaying techniques, forming the backbone of many construction projects. Their precision and attention to detail help ensure that a building is not only visually appealing but also structurally sound. The role of a brickwork contractor often goes beyond simply laying bricks; they collaborate closely with other professionals on-site, contributing to planning, design decisions and problem-solving, ensuring a project’s success. From laying the first brick to applying the finishing touches, brickwork contractors help shape our built environment one brick at a time.

Index

a) A Brief History

b) The Importance of Brickwork in Construction

ii) Understanding The Basics of Bricks

a) What are bricks made from

b) Different sizes and standards of bricks

c) Factors determining the quality of bricks

iii) Different Types of Bricks and Their Uses

a) Burnt Clay Bricks

b) Sand Lime Bricks

c) Engineering Bricks

d) Concrete Bricks

e) Speciality and Eco-friendly Bricks

iv) Colour and Texture of Bricks

a) How bricks get their colour

b) Textural variations and their effects

a) English Bond

b) Flemish Bond

c) Stretcher Bond

d) Header Bond

e) Choosing the right brick bond for your project

vi) Brick Mortar and Best Practice

a) Mortar Mix

b) Portland Cement

c) Lime Mortar

1) Hydrolic Lime Mortar

2) Non-Hydrolic Lime Mortar

d) The significance of curing and weather considerations

1) Hot Weather Brick Laying

2) Cold Weather Bricklaying

e) Health & Safety Measures

I. Introduction to Brickwork

a) Brief History of Brick making

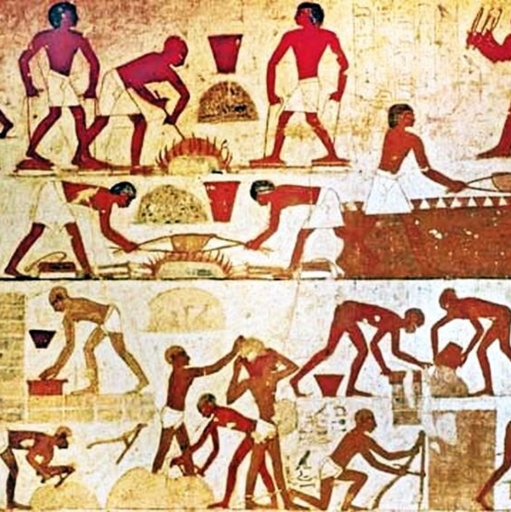

The art of brick making can be traced back to some of the oldest civilisations in the world. Evidence of brick use has been found in archaeological sites dating back to 7000 BC in regions now established as modern-day Syria and Turkey. As early as 3000 BC, the ancient Egyptians, Indus Valley Civilization, and people in the Middle East were using bricks to construct substantial buildings, showcasing the durability and utility of this construction material.

Brick making techniques gradually evolved from simple sun-dried mud bricks to more complex processes that involved firing clay bricks in kilns. This method produced stronger, more durable bricks. This evolution marked a turning point in architectural and construction history, paving the way for some of the world’s most iconic brick structures, from the Roman aqueducts to the Great Wall of China and the red brick buildings of the Industrial Revolution.

b) The Importance of Brickwork in Construction

For good reasons, brickwork has played a vital role in construction for thousands of years. Bricks are known for their durability, longevity, and resilience. They offer excellent resistance to harsh weather conditions and natural disasters, providing safety and structural integrity.

Bricks also possess excellent thermal properties, retaining heat in the winter and keeping interiors cool in the summer, enhancing energy efficiency. Moreover, bricks require minimal maintenance, which makes them a cost-effective option in the long run.

Brickwork is not just about functionality; it’s also about aesthetics. The warm, natural look of bricks has a timeless appeal that enhances the architectural style of structures, be it traditional or contemporary. From residential buildings to commercial and industrial work spaces, brickwork offers an enduring charm that few other construction materials can match.

In the modern era, brickwork continues to be a popular choice in the construction industry. Its versatility and advancements in manufacturing techniques allow for a broad range of applications, including walls, pavements, and decorative features, marking it as a crucial aspect of our built environment.

II. Understanding the Basics of Bricks

a) What are Bricks Made From?

At their most basic, bricks are made from clay and shale – two of the earth’s most abundant natural resources. These materials are ground and mixed together, then formed into the rectangular shape we commonly associate with bricks. Once shaped, they are fired in a kiln at very high temperatures, which increases their strength and durability. Bricks can also contain other materials to enhance specific properties, such as resistance to fire or water absorption.

b) Different Sizes and Standards of Bricks

The size of bricks can vary greatly depending on regional influences, specific building requirements, or historical traditions. Standard brick sizes have been established in various countries to ensure compatibility and uniformity in construction projects.

In the United Kingdom, the most commonly used brick size in modern construction is 215 × 102.5 × 65 mm.

However, in the restoration or extension of older buildings, “imperial-sized” bricks are often used to match the dimensions and appearance of the existing brickwork. The imperial standard brick size, primarily used before the country adopted the metric system, is approximately 9 x 4.5 x 3 inches. When working on older buildings, these slightly larger dimensions can be critical to maintaining aesthetic consistency and structural integrity.

Therefore, it’s essential to be aware of these variations in brick sizes, especially in projects involving older structures where standard metric-sized bricks may not be suitable.

C. Factors Determining the Quality of Bricks

Several factors determine the quality of bricks, and it’s crucial to be aware of them to ensure optimal brickwork:

-

- Composition: High-quality bricks should have a uniform composition and no noticeable impurities.

- Shape and Size: Bricks should have uniform and standard size and shape, with sharp and square edges.

- Colour: The colour of a brick, usually red, brown, grey or blue, is a good indicator of its quality. It should be uniform throughout the brick.

- Texture: A quality brick should have a fine, compact, and uniform texture.

- Strength: The strength of a brick should be sufficient to withstand the weight and forces acting upon it in a structure. Bricks should have a minimum compressive strength of 9N/mm² for a building up to two storeys high and 13N/mm² for anything higher. If the crushing strength of a brick is below 3.5N/mm², it should not be used.

- Soundness: A high-quality brick should produce a clear metallic ringing sound when struck.

- Water Absorption: The optimal water absorption rate for clay bricks falls within the range of 12% to 20%. For projects involving engineering bricks, aiming towards the lower end of this range, around 12%, is preferable to achieve superior outcomes. However, if water absorption drops too low, dipping below 12%, it could compromise the ability to form a solid bond between the bricks and the mortar.

- Efflorescence: Quality bricks should have a minimal quantity of soluble salts. If these salts are present in large amounts, they will appear as white patches when the brick dries after absorbing water.

Knowing these factors can guide construction professionals in choosing the best bricks for their projects, ensuring that the final brickwork is both durable and aesthetically pleasing.

III. Different Types of Bricks and Their Uses

a) Burnt Clay Bricks

Burnt clay bricks are one of the oldest and most common bricks used in construction. They are made by pressing clay into moulds and then firing them in a kiln. These bricks are robust, durable, and offer good insulation properties. Their uses range from constructing walls to groundworks and external facades.

b) Sand Lime Bricks

Sand lime bricks, also known as calcium silicate bricks, are made by mixing sand, fly ash, and lime, followed by a chemical process during wet mixing. The mix is then moulded under pressure forming the brick. These bricks have a uniform pale grey colour. Because of their smooth finishes, they can be used in architectural applications that require highly detailed features or decorative effects.

c) Engineering Bricks

Engineering bricks are specially made for their physical characteristics of strength, low water absorption and excellent frost resistance. In the UK, engineering bricks come in two classifications: Class A and Class B. Class A bricks exhibit a minimum compressive strength of 125N/mm2 and a maximum water absorption rate of 4.5%. They are categorised as F2 for freeze-thaw durability and S2 for active soluble salt content. On the other hand, Class B bricks possess a lower minimum compressive strength of 75N/mm2 and a slightly higher maximum water absorption rate of 7%. Like Class A, they are rated F2 for freeze-thaw durability and S2 for active soluble salt content.

d) Concrete Bricks

Concrete bricks are a versatile type of brick made from concrete. They are typically used in fences, facades and provide sound and heat insulation. These bricks are favoured for their high compressive strength and durability.

e) Specialty and Eco-Friendly Bricks

In response to growing environmental concerns, various eco-friendly bricks have gained attention. One such type, yet to be widely adopted in the UK but common in other regions such as India, is the Fly Ash Clay Brick (also known as FAB or FaL-G brick).

FABs are formed by mixing fly ash, an industrial by-product from coal-fired power plants, with clay. This technique effectively reduces the amount of clay required while providing practical use for fly ash. Without proper repurposing, fly ash can contribute to environmental pollution.

The UK’s brick market is primarily dominated by traditional clay and concrete bricks. However, there is a palpable shift towards sustainable and environmentally conscious alternatives. Considering this trend, it wouldn’t be surprising to see a rise in the future use of FABs and other eco-friendly bricks. As the brick industry continues to evolve, it’s recommended to stay updated with the latest resources and regulations to make the most informed decisions.

IV. Color and Texture in Bricks

a) How Bricks Get Their Color

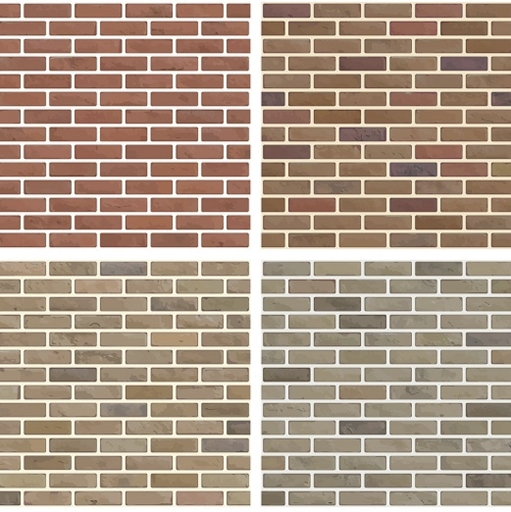

The colour of bricks is determined by a few key factors, the most significant of which is the composition of the clay used to make them. Clay contains various minerals, each of which can affect the final colour of the brick. For instance, red bricks get their distinctive hue from the high iron content in the clay, while yellow bricks have a high content of lime.

Another major factor influencing brick colour is the temperature at which the bricks are fired. Higher temperatures intensify the colour, while lower temperatures produce more subdued tones. The oxygen levels in the kiln during firing can also affect the colour. Higher oxygen levels lead to oxidation, resulting in red or orange bricks. Lower oxygen levels can lead to reduction, causing the bricks to turn blue or purple. In the context of the brickmaking process, the term “reduction” refers to what happens when there’s limited oxygen in the kiln.

b) Textural Variations and Their Effects

Texture in bricks can add a unique visual dimension to a building. It can create an array of light and shadow effects that can dramatically enhance the aesthetic appeal of a structure. The texture of a brick is primarily determined by how the brick is manufactured.

Machine-made bricks often have a smooth and uniform texture, giving the structures a contemporary and minimalist look. Handmade bricks, on the other hand, have a more rustic and artisanal appearance due to their rough and irregular texture.

Extruded bricks, produced by pushing clay through a die, can have a range of textures from smooth to heavily textured, depending on the finish applied. Similarly, sand-faced bricks have a sandy texture achieved by dusting the mould with sand before forming the bricks.

The type of texture chosen can significantly impact the final appearance of the brickwork, adding depth, interest, and character to the finished structure. Therefore, both colour and texture are critical considerations when selecting bricks for a construction project.

V. Brick Bonds and Patterns

What is a Brick Bond?

A brick bond refers to the pattern in which bricks are laid to construct a wall or pavement. It not only contributes to the aesthetic appeal of the structure but also affects its strength and stability. The bond ensures that individual bricks share the load imposed on the wall, enhancing its structural integrity.

a) English Bond

The English bond is one of the oldest and strongest brick patterns. It consists of alternating courses of headers (bricks laid with their short end facing outwards) and stretchers (bricks laid flat and long). This pattern results in a robust, dense bond that’s ideal for load-bearing walls.

b) Flemish Bond

The Flemish bond, also known as the Dutch bond, is a decorative brick pattern that alternates headers and stretchers within the same course. The next course is laid so that a header is centred over a stretcher and vice versa, creating a distinctive checkerboard pattern. This bond is often used to construct walls where both faces are visible.

c) Stretcher Bond

The stretcher or running bond is the simplest and most commonly used bond in modern construction. It consists of bricks laid flat and stretching across the wall’s length. The bricks in each successive course are offset by half a brick from the bricks in the course below. This bond is often used in walls that are one brick thick.

d) Header Bond

In the header bond, also known as the Spanish bond, only the headers are visible from the face of the wall, and all bricks are laid flat. This pattern creates a compact and solid wall, but it’s less commonly used than the others due to its relative lack of visual interest.

Choosing the Right Brick Bond for Your Project

Choosing the correct brick bond is an essential decision in a construction project. It’s not only about aesthetics but also about functionality and the structural requirements of the building. The type of bond chosen can significantly impact the brickwork’s strength, durability, and visual appeal, adding character and charm to the structure. The kind of bond used can also increase the brickwork cost as some brick bonds are more time intensive than others. It is crucial to choose a bond that aligns with the building’s design objectives and meets its structural needs and budget.

VI. Brickwork Mortar and Best Practices

A. Introduction

In the world of masonry, the choice of mortar significantly influences the construction’s quality, durability, and sustainability. The most commonly used mortar comprises Portland Cement due to its easy mixing and availability. It can even be ordered pre-mixed and stored in tubs ready for use.

B. Mortar Mix

The correct mortar mix is critical for durable and high-quality brickwork. Mortar binds bricks together, filling the gaps to ensure a strong and weather-resistant structure. Mortar is typically a mix of sand, cement, and water. Lime can be added to the mix to increase the mortar’s workability and durability. The type of sand used can also impact the mortar’s colour, strength, and weather resistance. Mortar dye is also available or can be ordered as part of a ready mix supplied.

C. Portland Cement Mortar

Portland Cement Mortar is a staple in modern construction, revered for its strength and durability. It’s typically made from a blend of Portland cement, sand, and water. The standard mix ratio is often 1 part Portland cement to 4 parts sand, which can be adjusted based on the project’s requirements.

Properties: This type of mortar is known for its strong bonding capabilities and quick setting time, making it ideal for contemporary construction where structural integrity is crucial.

Applications: Perfect for general construction, load-bearing walls, and areas that require robust structural support.

Mixing and Applying: It should be mixed in small batches to maintain consistency. Apply evenly with a trowel, ensuring strong adhesion and a clean finish.

Lime Mortar is often the preferred choice for specific projects, typically renovation or heritage projects.

D. Lime Mortar

There are different types of lime mortar, each with unique properties and uses. The classes are primarily defined by the kind of lime used and the addition of other materials. The main types of lime mortar are:

1. Hydraulic Lime Mortar

Composition: Made from hydraulic lime, which contains clay and other impurities that allow it to set through hydraulic reaction in addition to carbonation.

Types: Classified into different strengths (feebly, moderately, and eminently hydraulic lime), depending on the clay content and the setting speed.

Setting Process: Can set under water or in damp conditions, making it more versatile than non-hydraulic lime mortar.

Properties: This mortar is breathable, flexible, and suitable for damp conditions. It’s environmentally friendlier than cement and is excellent for historic restoration.

Applications: Ideal for restoration projects, older buildings, and areas with moisture issues. It’s also used in new construction for its aesthetic and ecological benefits.

Mixing and Applying: Similar to cement mortar but requires attention to water content and setting times.

2. Non-Hydraulic Lime Mortar

Composition: Made from lime putty or fat lime (calcium hydroxide), which is lime that has been slaked with water.

Setting Process: It sets slowly through carbonation, reacting with carbon dioxide in the air to form calcium carbonate.

Uses: Ideal for conservation and restoration work, especially in buildings that require a mortar with good breathability and flexibility. It’s not suitable for damp conditions or for areas exposed to water.

E. An Overview of Bricklaying

Given the subject’s vast nature, bricklaying can’t be covered in this article.

More detailed resources and professional guidance should be sought for a comprehensive understanding and successful execution of bricklaying.

F. The Significance of Curing and Weather Considerations

After laying the bricks, the mortar must undergo a crucial curing phase. This step involves a slow drying process allowing the mortar to reach its maximum strength. Usual techniques include covering the brickwork with a protective sheet or frequently wetting the surface to prevent rapid drying.

However, weather conditions play a significant role in this process, particularly in extremely hot or freezing temperatures:

1) Hot Weather Bricklaying: In hot conditions, mortar can dry out too quickly, weakening the bond between the bricks. To mitigate this, you can use retarders to slow down the setting process, cool the materials used in the mix, adjust the mixing quantities to prevent premature drying and hydrate the bricks before laying them. Providing shade for the working area and covering the brickwork can also help to slow the evaporation rate. Often, it’s best to start work early in the morning or later in the evening when temperatures are cooler.

2) Cold Weather Bricklaying: In freezing conditions, it’s essential to prevent the mortar from freezing, as this can compromise the strength and durability of the brickwork. Strategies include using antifreeze admixtures, storing materials in a warm, dry place, heating the materials, and protecting the brickwork with insulating blankets or heated enclosures. It’s also advisable to avoid laying bricks when the temperature is at or below freezing point or if such conditions are expected within 24 hours of laying the bricks.

Weather conditions greatly affect brickwork and require specific strategies to ensure a robust and durable structure. By understanding and adapting to these challenges, construction professionals can create brickwork that withstands the elements and time.

G. Health and Safety Measures

Brickwork involves some risks, and following health and safety guidelines is essential. This includes wearing protective clothing such as gloves and safety glasses, using the correct tools, and adhering to safe lifting techniques to prevent injury.

VII. The Integral Role of Brickwork Contractors

In the vast expanse of construction, brickwork contractors stand out due to their specialised expertise and contributions. These professionals aren’t just about placing bricks together; their role is multifaceted and essential to the entire construction process:

Technical Expertise: From understanding the nuances of different brick types to knowing the correct mortar mix, brickwork contractors bring invaluable knowledge to every project.

- Craftsmanship: Beyond the technicalities, there lies an art in brickwork. A craftsman’s touch requires a perfect alignment, ensuring mortar consistency and creating an aesthetic appeal.

- Structural Integrity: One cannot overemphasise the importance of a building’s strength and longevity. The foundation of this lies in the quality of its brickwork, and contractors are pivotal in ensuring it adheres to the highest standards.

- Project Planning: Their collaboration continues beyond brick and mortar. Brickwork contractors often join forces with architects, engineers, and project managers right from the planning and design phases, bringing practical insights that can avert potential challenges.

- Cost Management: Their expertise extends to advising on the most cost-effective materials and techniques, which ensures projects achieve financial efficiency without compromising quality.

- Problem-Solving: Construction comes with its fair share of unpredictabilities. Be it adverse weather conditions, material shortages, or site-specific issues; brickwork contractors bring solutions to the forefront.

- Collaboration: The brickwork might be their forte, but contractors work in tandem with various other tradespeople. Their coordinated efforts ensure harmonious progress throughout the construction phase.

- Maintaining Standards: Every brick laid and every structure erected has to comply with stringent building codes, local regulations, and industry benchmarks, thanks to the vigilance and commitment of brickwork contractors.

In the grand tapestry of construction, brickwork contractors embroider the details that transform a design blueprint into a lasting, tangible structure. Their expertise ensures the buildings are architecturally sound and stand as a testament to aesthetic grace and resilience.

VIII. Conclusion

Brickwork is an integral part of the construction world. With their history dating back thousands of years, bricks have proven their resilience and versatility, and they remain a preferred material for many builders today. The options are almost limitless, from the different types, sizes, and colours of bricks to the various bonds and patterns in which they can be laid.

Choosing the right brick and bond for your construction project requires careful consideration of the structural requirements and the desired aesthetic outcome. Understanding the distinct characteristics and uses of each type of brick and the importance of different brick bonds can help ensure the success of a construction project.

Properly executed brickwork techniques and regular maintenance can result in durable and visually appealing structures that stand the test of time. Whether it’s a residential house, a commercial building, or a simple garden wall, the beauty of brickwork is truly in the details.

This guide reflects our deep respect for the mastery of brickwork and the talented contractors contributing to our projects. Being a prominent construction company based in the West Midlands, we are continuously on the lookout for committed brickwork contractors who align with our standards of excellence and craftsmanship.

Should you be interested in joining a team that greatly values your skills and expertise, we invite you to explore potential opportunities with us. By working together, we can persistently contribute to our built environment, maintaining a steadfast focus on quality and innovation that forms the core of our work.

Do you you need help with your construction project? If you have a project you’d like to discuss with us, feel free to contact us; we’d love to help.

Call us on 01902 595 145 for more information.